01

Suzhou Jinxie Medical Equipment Factory was founded in 1995. So far, it has a history of more than 30 years. Located in the most economically developed eastern coastal area of China, in the center of the Yangtze River Delta - Suzhou area, which is not only the birthplace of China's orthopaedic medical device industry, but also the silicon valley of orthopaedic medical device product production, research and development.

We mainly produce implantable materials and tools for medical devices, and we are a member of Jiangsu Medical Devices Industry Association and a key enterprise of China Quality Trustworthy. The main products of our company are: orthopedic series products: unilateral one-piece external fixation bracket, combined external fixation bracket, spinal fixation instruments, orthopedic implants, medical electric saw, drill, nucleus pulposus forceps, conical plate forceps, bi-articular bone biting forceps, limb trauma, vertebroplasty system, complete sets of instrumentation kits; rehabilitation and home use wearable products: medical external fixation device, medical external fixation brace, thoracic and lumbar fixation device, lumbar protection belt, adult and child scoliosis braces for adults and children.

The Jinxie factory has obtained MDR-CE certification and ISO·13485 quality management system certification in 2024. The factory's strong OEM capabilities can meet the requirements of global customers.

“The factory always adheres to the tenet of “Quality First, Service Oriented”, the concept of “Be careful with the end as the beginning, keep improving”, and the pursuit of “Human Health, Our Hope”. Human health, our hope” for the mission. The factory integrates R&D, production, testing, and OEM service concepts, and is committed to providing timely and high-quality products for global customers.

02

Jinxie people are committed to the maintenance of the earth's environment and social welfare undertakings, actively participate in the protection of the environment, so that the earth is more beautiful, human beings more healthy ideas; participation in public welfare undertakings, maintain a high degree of social responsibility; committed to orthopaedic products, technological innovation, and always customer-centered to provide customers with high-quality, safe, and effective high-quality products, and make every effort to build “Jinxie We are committed to the technological innovation of orthopedic products, always customer-centered, providing customers with high-quality, safe and effective quality products, making every effort to build the “Jinxie” brand, and making unremitting efforts for the medical and health industry of mankind.

Our Spirit: Realistic, Precise, Innovative

Our Philosophy: Excellence, Harmony, Pragmatism

Our vision: customer-oriented, and actively build the “Jinxie” international brand.

Our Mission: To serve for the health of human beings.

Our Quality Policy: Pursue scientific management mode.

Pursuing excellent product quality.

Provide value-added customer service.

Implementing a scientific management model

Pursuit of superior product quality

Provide great value customer service

The rate of products passing the first delivery inspection ≥95%.

Customer satisfaction ≥ 90%, increasing by 0.5% per year.

Products from the factory comply with regulations, standards and user requirements.

Provide an appropriate response to customer complaints within 48 hours

30+

Industry experience

100

Number of employees

30%

Annual turnover growth rate

03

Our factory has a team of 5 highly qualified and creative professionals in design and development. The team members cover medical experts, engineers, designers and other talents in various fields, who, with their rich industry experience and professional knowledge, inject a strong impetus into the design and development of products. We are equipped with advanced research and development equipment and testing laboratories, which can accurately conduct various technical tests and simulation experiments. From conceptual design to product formation, every step of the process is strictly controlled and optimized to ensure the safety, effectiveness and reliability of our products.

The factory owns American Hardinge vertical 4-axis and 5-axis machining centers, and its series of machines have unique overall stability, milling surfaces, holes, and slots can reach precise accuracy. Rigid tapping is that its spindle rotation is strictly synchronized with the Z-axis, which enables standard tools to perform precision and fast tapping. Our factory introduced several Japanese Cincom (Citizen) L20 type CNC centering machines in 2019 The machine supports a maximum diameter of up to 25mm; a clamping processing length of up to 200mm; guide sleeve type without guide sleeve type interchangeable function, equipped with B-axis row of rotary tool, can be oblique hole processing, tool table Y-axis design, to meet the processing of anisotropic workpieces, to achieve composite processing, overlap machining; power unit, torque is greater, rigidity is stronger, the machining accuracy is more stable.

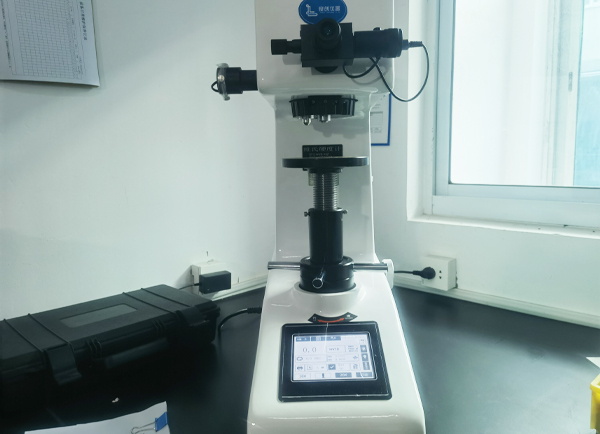

Our factory will control all kinds of metallic or non-metallic materials that come into the factory and will test the hardness of each batch of raw materials. The positive quadrangular cone diamond indenter is pressed into the surface of the material, the diagonal length of the indentation is measured, and the Vickers hardness value of the material is calculated. The measurement results of this equipment are accurate and stable, with high resolution, and can distinguish materials with small differences in hardness.

Ultrasonic Flaw Detector - It is capable of detecting, localizing, evaluating and diagnosing a wide range of defects (cracks, sparsity, porosity, inclusions, etc.) within the workpiece quickly, easily, non-destructively and accurately.

Height Measuring Instrument ---- is mainly used to measure the height of the workpiece, but also can measure the shape and positional tolerance dimensions, and also can be used to measure the depth, slot width, internal and external hole diameter, the highest point, the lowest point, the flatness, the angle and so on;

Metallographic analyzer ---- is used to identify and analyze all kinds of metals, castings, alloy materials, plating combination structure of entering the factory to ensure the safety and reliability of each batch of raw materials, so as to ensure the quality of the product without defects.

Universal can tensile machine ------ used for a variety of materials for instrumentation static load, tensile, compression, bending, shear, tearing, peeling and other mechanical properties test with the mechanical force of the test machine;

Our factory has passed ISO 9001 and ISO 13485 quality system certification in 2019, and is committed to meeting the individual needs of customers. We have a sound quality system: according to the regulations, we have established a "Quality Manual" and "Procedure Documents" that will be produced Products undergo standardized record control. According to the process of the quality management system, quality activities such as production, inspection, design and development, process verification, supply chain management, and continuous improvement are all under control, allowing us to provide customers around the world with higher precision, better performance, and Products and services that are safe, reliable and with controllable risks.

Process Validation: When product development enters the pilot production stage or when a new process is adopted, the quality department of JHI will perform process validation.

Through IQ, PQ and OQ, including product design, process design, equipment and fixtures, materials, environment, personnel, inspection program, measurement system, etc., to ensure the standard and planned pass rate of each workpiece.